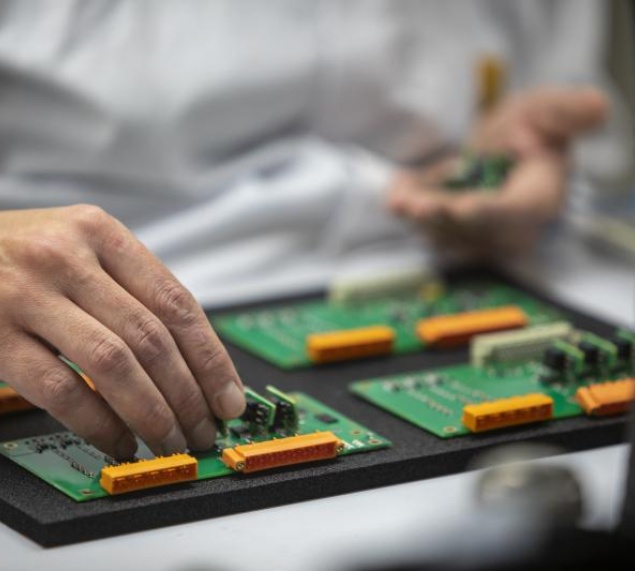

Today, PCBs (printed circuit boards) are the fundamental building blocks of electronics, enabling the integration of components into compact and efficient devices. High-quality PCB assembly ensures reliable and long-lasting functionality of electronic devices, reduces the risk of errors, and increases the overall value of the product.

Our three SMT (Surface Mount Technology) lines are equipped with the latest robotic systems, allowing for fast and precise placement of components on PCBs.

Advantages of SMT assembly include higher component density, lower production costs, and faster manufacturing compared to traditional methods.

Reflow soldering is a popular method in the electronics industry due to its high efficiency, automation possibility, and ability to achieve a high degree of accuracy and repeatability.

Tin paste application using screen printing is a process used for applying hot melt material to printed circuit boards (PCBs) before soldering components. This procedure ensures that the paste is applied evenly and accurately to specific areas of the PCB, which is essential for high-quality and reliable soldering of components.

When assembling SMT components, it is important to comply with specific requirements and standards to maintain the quality and reliability of the final product. We have installed four MYDATA placement machines on our three SMT lines: MY100DX, MY200LX, MY300LX and MY300DX.

For optical inspection of assembled printed circuit boards, we use AOI CyberOptics SQ3000. AOI (Automated Optical Inspection) is a technology used for the inspection of printed circuit boards (PCBs).

SMD (Surface Mount Device) components are an important part of modern electronics. The storage and handling of these components requires a careful and efficient solution that minimizes the risk of damage and loss.

THT (Through-Hole Technology) is a traditional method of mounting electronic components on printed circuit boards (PCBs). In THT technology, components are mounted in holes in the PCB and then soldered.

After soldering, the PCB is often cleaned to remove any flux residue or dirt. For this purpose, we use the Injet 388 TWIN CRRD automatic cleaning machine.

Do you have questions, comments or are you just curious? We are here for you! Contact us through the channels below or using the form.